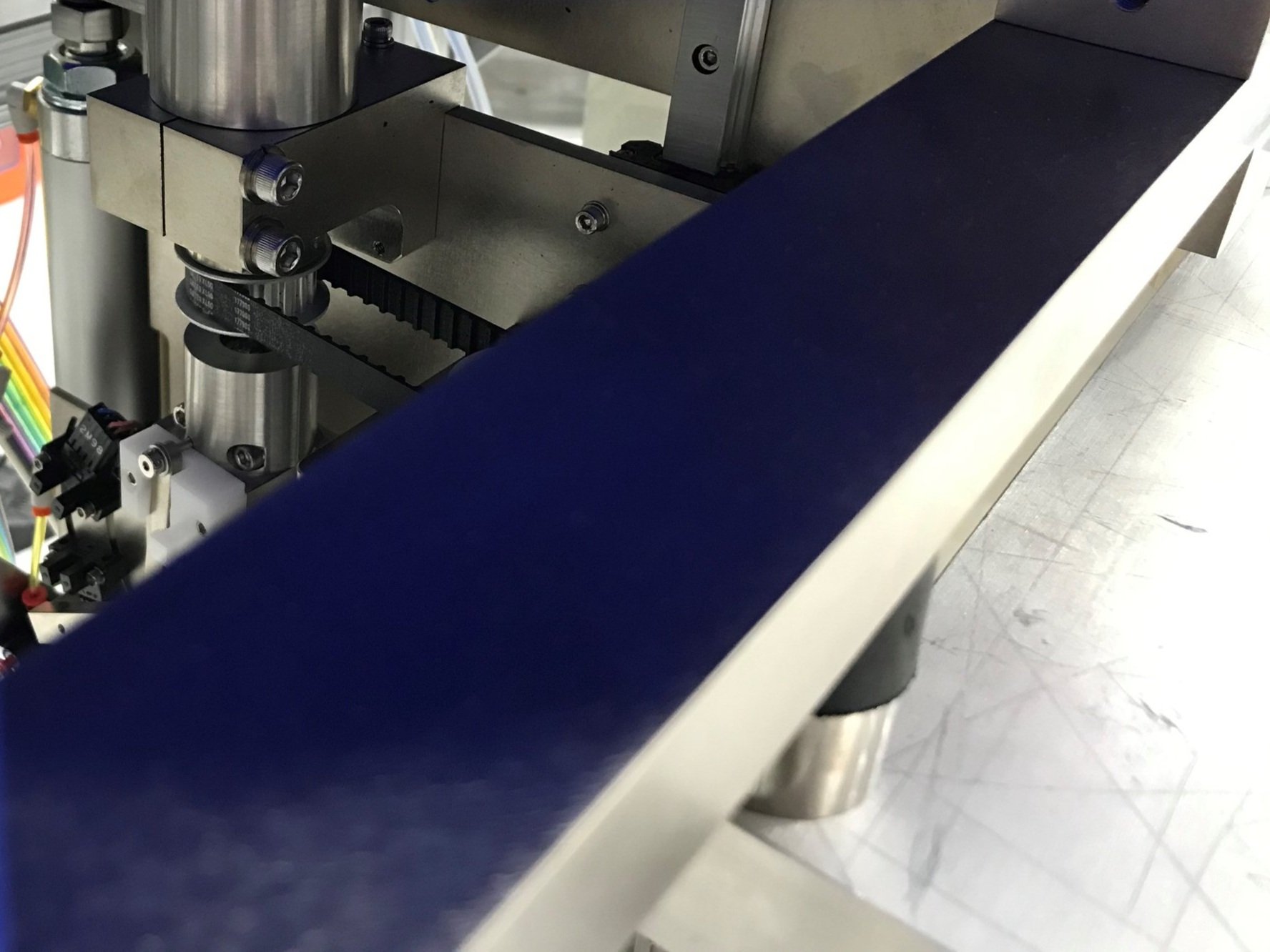

Modern parts solutions for your new and legacy CMP polishers

If you need CMP replacement parts or other CMP equipment, we have you covered. Entrepix allows you to sustain and improve your existing hardware.

Every part we make is of the highest quality and designed to meet or exceed OEM standards.

We can develop entirely new products, like our original wafer carriers or our cleaning modules, but we also create simple parts solutions for your existing equipment needs. Addressing niche replacement parts applications, reverse-engineering old assemblies, and adapting old technology for new uses are some of our specialties.

Need to fine-tune your chemical mechanical polishing or cleaning process? Need parts support for your new, current, or legacy application? Trying to reign in obsolescence issues? Our engineering teams can design parts to your (or the OEM’s) specification, change what’s in your kits, and offer support to get you the results you need.

Plus, our 3D printers and in-house machining and fabrication capabilities enable rapid prototyping to speed up your time to market and increase your efficiency.

Your Source for CMP Spare Parts

Entrepix has a massive inventory of spare parts for cleaning and CMP platforms like OnTrak, AMAT Mirra, IPEC, and SpeedFam, as well as for Rudolph metrology equipment and other technology. We also stock obsolete parts to keep your legacy systems humming.

Engineered Parts for New Capabilities and CMP Equipment Upgrades

Can’t find the replacement part you’re looking for? Entrepix can make it.

Are you imagining a part with new capabilities that doesn’t exist? Entrepix can make it.

Our team of engineers can create custom solutions that breathe new life into your CMP platforms.

Proven Solutions for CMP Equipment Obsolescence

We develop proven solutions to equipment and part obsolescence for our clients and for ourselves. We don’t just replicate, we innovate. By asking how things can be improved, we challenge ourselves to devise and optimize.

Entrepix continues to support equipment that OEMs do not, and we even support equipment for which OEMs no longer exist, such as the IPEC 472.

Replacing the Obsolete OEM GESPAC with a Windows Based PC

Entrepix replaced the obsolete OEM GESPAC computer system in a legacy OnTrak and replaced the entire system with a Windows 7 Embedded industrial PC.

The upgrade included:

A solid state hard drive

Full SECS/GEM via HSMS

Full data capture and logging by wafer, lot ID, module, or user ID

User-defined alarm set points by wafer counts or elapsed time

Improved wafer recovery and teach screens

Enhanced security features by user

Support for advanced motion controllers, distributed I/O, sensor monitoring by factory automation

This brings the entire piece of equipment into modern times while maintaining a high level of backwards compatibility, as the client can now network the OnTrak into their facility and continue to run and upgrade their system for years to come.

Managing Your CMP Cleaner Obsolescence Problems

Need a part that’s obsolete? We’ll make it for you. Tell us about what you need and we’ll reply shortly.