The New Entrepix DSS-200

The modern OnTrak optimized for increased throughput, ready for the future

The new generation OnTrak system is here, directly from the OEM

The modernized Entrepix DSS-200 double-sided post-CMP wafer cleaner offers the same familiar functionality as the legacy OnTrak system with numerous upgrades for today’s cleaning process demands.

As the OEM for OnTrak systems, Entrepix has engineered the NEW DSS-200 OnTrak for reliability and longevity with support and spares you can depend on.

Our DSS-200 cleaners offer:

Parts exchangeability with legacy OnTrak systems

Replacement and modernization of obsolete parts

Configuration for 100-200mm substrate

Accommodation for smaller wafers with custom-designed carriers

The DSS-200 comes in three configurations: CE, Synergy, and Integra.

DSS-200 applications include:

Post-CMP clean

Pre-bond clean

Pre-photo clean

Advanced packaging applications

Post-metal deposition

Post-ILD deposition

Post-scribe

Substrate manufacturing

OnTrak Upgrades

Upgrades for legacy OnTrak systems with OEM support are available for you, ready to go when you are. Upgrade options include:

Control system and software upgrade

Hastelloy spin carriage

High efficiency heat lamp

Megasonic cleaning

DI water conservation

Through-the-brush delivery

Inline mix dilution

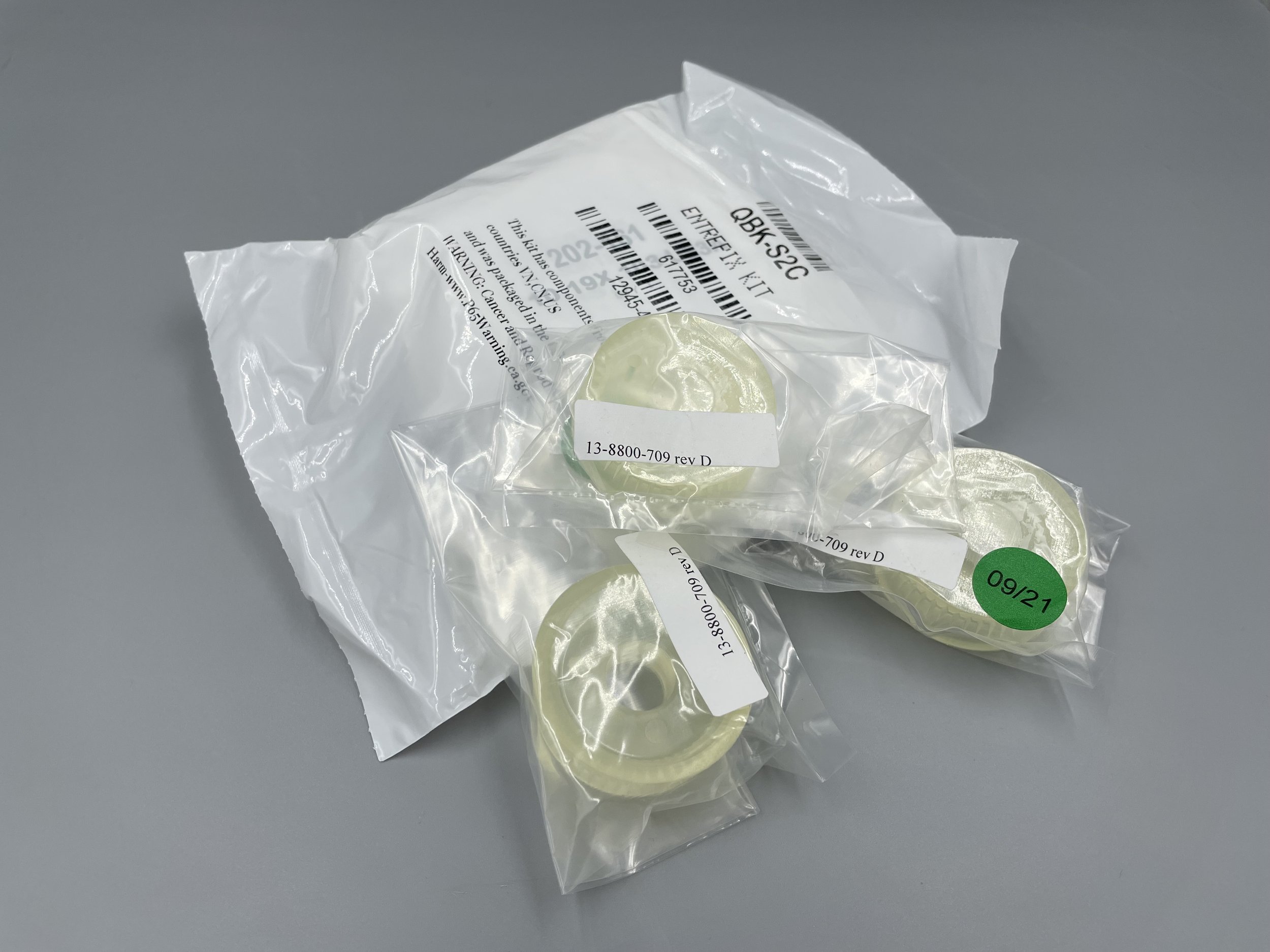

OnTrak Parts Support

Entrepix provides high quality OEM components not only for the new generation of DSS-200 cleaners, but also for the Lam OnTrak DSS Series 1, Series 2 Classic and CE, Synergy, and Integra platforms.

All OnTrak parts are selected or designed to meet and exceed original standards. We provide thorough incoming and outgoing inspections to ensure our customers get exactly what they need.

PM Kit Custom Solutions

Whether you have a brand new DSS-200 with a standard configuration, or have a decades-proven OnTrak system with a multitude of customizations, we have a PM kit for you. Our group of experts and engineers can advise you on the best solution to fit your needs and can assemble together a PM kit for your specific application.

| Entrepix Series 2 CE | Entrepix Synergy | Entrepix Integra | |

|---|---|---|---|

| Cleaning Method | Brush Scrub | Brush Scrub | Brush Scrub |

| Integrated | No | No | Yes |

| Brush Type | Roller PVA | Roller PVA | Roller PVA |

| Downforce Control | Yes | Yes | Yes |

| Edge Scrub | Optional | Optional | Optional |

| MegPie™ Megasonic Transducer | Optional | Optional | Optional |

| Megasonic Nozzle | Optional | Optional | Optional |

| High-Pressure DI Water Spray | Optional | Optional | Optional |

| Heated DI Water Feed | Optional | Optional | Optional |

| Drying Method | Spin + Heat Lamp | Spin + Heat Lamp | Spin + Heat Lamp |

| NH4OH | Yes | Yes | Yes |

| dHF | No | Yes | Yes |

| SC-1 | Pre-Diluted: Yes | Yes | Yes |

| SC-2 | Citric-Based: Yes | Citric OR HCL-Based: Yes | Citric OR HCL-Based: Yes |

| Backside Chemical | Yes | Yes | Yes |

| Metal CMP Cleans | Yes | Yes | Yes |

| STI CMP Cleans | Yes | Yes | Yes |

| Double Contained Process Area | No | Yes | Yes |