Bringing Innovation to CMP Equipment

Need something custom-designed for your niche application? Entrepix will make it.

Our Engineered Products Increase Your Tool Performance, Reliability and Uptime.

There’s another tool in your quest for process improvement, obsolescence mitigation, and nearly any type of engineering work desired: Entrepix. Our engineering team has experts in mechanical, electrical, and software engineering who can create and replicate anything you need to OEM standards.

We discover new product opportunities every day through our field service team working with customers and their machines, via sales talking to clients, from product managers who need new tool capabilities, and from our internal experts and engineers who work with CMP equipment every day. Plus, we often have new contacts reach out to us asking if we can help them solve a problem.

After our engineers get a rundown, they figure out what’s possible and make it happen. Utilizing our rapid prototyping capabilities, including our own Advanced Fabrication Center and 3D printers, our engineers can have a prototype in hand the same day a part is designed.

That’s why we think of our engineers not just as an internal team, but as a concierge service for our clients - because they’ll create what you need, when you need it.

Let Us Actualize Your Solution

Customized Polishing Heads

Entrepix not only produces Titan, Profiler, and other CMP heads in spare part and standard replacement forms, but also customizes internal parts to achieve the accurate results your process demands.

Electromechanical Development

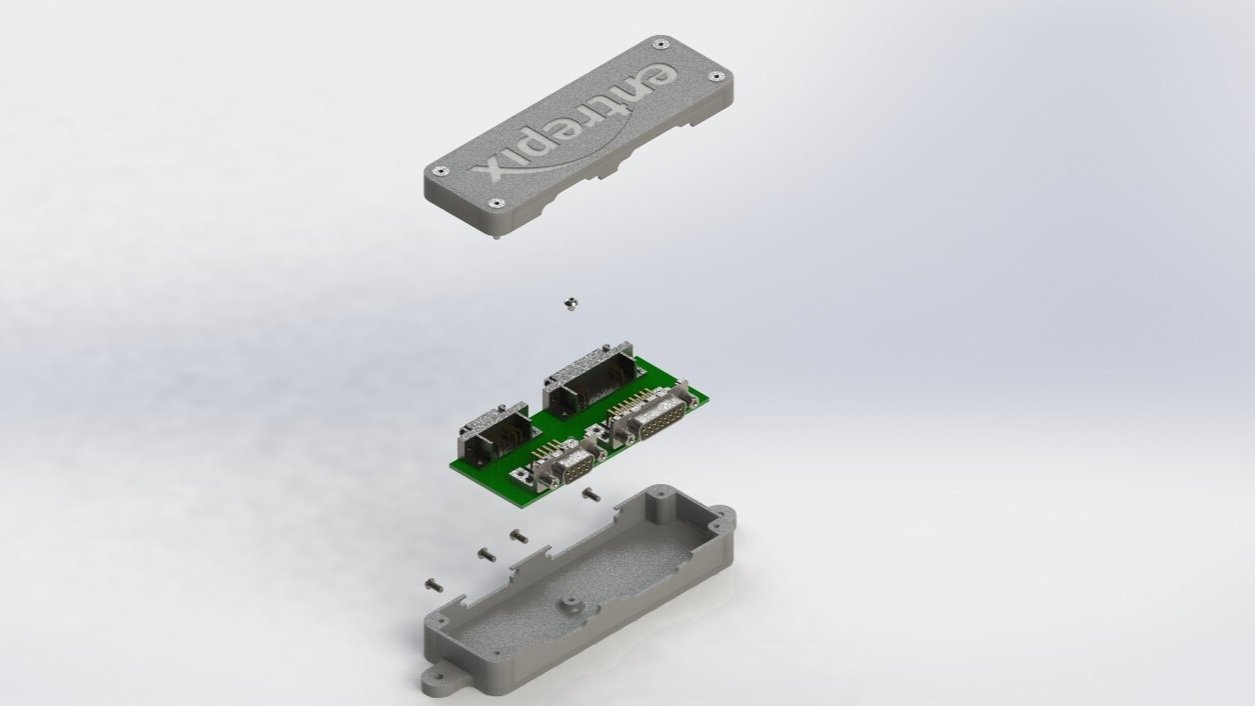

Our team can develop nearly any electrical, mechanical, software, or combined solution you require, from an enclosed PCB like above to an entire tool created and customized to your application.

Wafer Carriers

Entrepix can custom-develop wafer carriers for your polishing and cleaning needs. Our team can devise and rapidly produce solutions for many sizes, substrates, and processes using high-quality and high-purity materials.

IPEC 472 Advanced Head Load Station

Our engineers specialize in expanding the functionality of legacy equipment using minimally invasive techniques that maximize reliability and process improvement, such as in development of this upgraded IPEC 472 load station.

Slurry Flow Monitor

Make your request reality! One of our customers requested a simple solution to monitor slurry flow in their Mirra CMP tools, and the solution our engineering team turned out requires no drilling, cutting, splicing, or other invasive procedures that may compromise reliability and uptime.

Clear Pad Conditioner Cover

Some of the best solutions are the simplest - the clear pad conditioner cover that Entrepix engineered for Mirra CMP tools allows for easy monitoring of the inner workings of the assembly, while also being quicker and easier to remove when it is time for service.

We’ll Make A Custom Part For You

Got something you need but can’t find? We’ll make it for you. Let us know what you need and we’ll reply shortly.